Canada Blower Co. has

developed Low Profile Positive Pressure Ventilators that have been

designed to fit in tight compartments and small spaces without

sacrificing performance or features. These compact ventilation blowers

are available is both gasoline driven configuration and with 115/230V

single phase electric motor:

Canada Blower Positive Pressure Blower is a high volume fan use to

pressurize a burning structure, in case of fire, in order to force the

smoke out. Canada Blower Positive Pressure Blowers are portable,

gasoline powered fans, most of which utilize a 5.5 horsepower engine.

The theory of positive pressure ventilation is based on the principal

of even pressure distribution. Once a structure is pressurized, air and

smoke can be forced out through any opening (similar to escaping from

an inflated balloon).

Canada Blower electric smoke ejectors (negative pressure ventilation)

can be used for smoke removal but this has proven to be inferior to

positive pressure ventilation:

What makes Canada Blower Positive Pressure Ventilation superior to

negative pressure ?

* The risk of injury from the engaged structure is reduced while

placing the fan in operation.

* Positive pressure ventilation is faster to set up and requires fewer

personnel.

* The Positive Pressure Blower has a self contained power source, while

electric fans require cords and adaptors.

* Smoke and heat is removed from all levels of the structure unlike

negative pressure which can result in localized extraction.

* Quicker results. After initial knockdown, positive pressure

ventilation can be initiated and will show immediate improvements in

the interior conditions.

* It allows replacement of contaminants with vital cooler, cleaner air

- especially in sealed or windowless buildings. It's also very

effective in large and compartmentalized buildings, warehouses,

schools, etc.

* Quick results allow firefighters faster entry due to lower heat

levels and improved visibility.

The following criteria should be considered for effective use of

Positive Ventilation:

- The cone of air must cover the intake opening.

The fan must be placed the correct distance from the structure such as

that the cone of air forms a seal around the opening.

- The size and location of the discharge is important.

The blower discharge, if at all possible should be as high and far away

from the intake as is practical. The discharge size should be between

3/4 to 1/2 times the intake. This may not always be possible as the

fire may have already dictated discharge locations and sizes; but

whenever there is a choice, the above criteria should be used.

- It is important to control the air flow between the intake and

discharge.

Positive pressure ventilation can move air long distances if proper

control is maintained by opening and closing doors, windows, etc. It is

important that firefighters understand not to open the structure too

much: ie breaking windows, etc.

The standard features of Canada Blower Positive Pressure Ventilators

include: fold down "T" handle; 8" pneumatic tires with full width axle;

a "tilt and lock" device that allows the unit to be angled 20 degrees

up or down with infinite positions in between; sturdy and light 1 inch

wrap around frame. Explosion proof electric motors are available as

drivers too.

The optimum Canada Blower ventilator placement distance on most 6' 6"

doors is about five to six feet away. If placement is too close, the

seal won't be achieved. If placement is too far away, the cone of air

will be hitting well outside the opening.

Backward

curved fan blowers in New York City and

Chicago, aerofoil / acoustafoil, or aerocline fan blowers with high

temperature

construction, stainless steel SS316, SS316L, SS304, aluminum, explosion

proof -

spark resistant construction, monel construction. Supply of replacement

backward

curved (BC) fan blowers and airfoil (AF), or acoustafoil (AcF), or

Aerocline

fan blower parts for backward curved bc fan blowers manufactured by

Buffalo

Blower - New York, Twin City Fan, Northern Blower, Chicago Blower,

Sheldons,

Cincinnati Fan, Hartzell, IAP, Industrial air products, Canadian

blower,

Aerovent, Penn Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent,

Alphair,

American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan,

Daltec, ABB,

Flakt, Flaktwoods, Woods, MK Plastics, Robinson Industrial, Garden City

Fan,

Loren Cook, Jen-air, Jenn Fan, Aeroflo, Grainger, Greenheck, Kice Fan,

ILG

Industries, Canada Fan, Industrial Air, Ceilcote

Widely recognized for design efficiency and integrity, Canada Blower

airfoil wheel has ideal characteristics for variable air volume

systems. The fan's deep spun inlet and hyperbolic wheel cone plus

generous fan housing proportions provide a smooth stable air flow over

the entire performance range. Precision balancing assures quieter

vibration-free operation that adds to the overall reliability and

performance of Canada Blower's airfoil fans.

Fans used in gas turbine systems are mounted onto gas-turbine generator

packages for use in power plants as well as on cruise ships, oil rig

platforms, and mobile generators. These systems are loaded onto

tractor-trailer rigs or barges and moved to a site to generate power

for events like the Super Bowl and concerts. Manufacturers of these

gas-turbine generators are realizing it pays to have the right fan for

the job from the start and are turning to Buffalo Fan to provide these

unique solutions.

In the past, the OEM purchased the necessary fan equipment then mounted

it on its gas turbine generators. These generator sets were then

shipped to job sites all over the world and installed in coastal areas,

jungles, deserts and other extreme locations (even water-based

applications like cruise ships and oil rig platforms). A key

requirement for these applications is that the fans need to be

exceptionally corrosion resistant to withstand these severe

environmental factors.

Noise attenuation is a major issue for power generators, both to

protect workers hearing and to keep operation at the quietest

level for any surrounding residential or business communities.

Power generation is a complex process. The power generation fan /

blower equipment should be tough enough to avoid operational failure

and to minimize installation and repair work. The rugged, high

performance fans Canadian Blower provided to a state-of-the-art hybrid

energy center, were ideal for the task. Canadian Blower was chosen for

this project because of their reputation for building large custom fans

for extreme industrial applications. The energy center s primary

requirement was that its chosen vendor be able to design and build a

set of the most rugged, efficient roof ventilators within budget. Most

roof ventilator fans last between 10 and 20 years when properly

maintained. Because of the permits and cost involved in performing

maintenance work on the roof of a power plant, they wanted their fans

to have a longer life span (up to 40 years). This lifespan requirement

meant that the fans had to be constructed using industrial grade

materials and components.

Canadian Blower propellers provide equal airflow in both directions.

Other companies fans have a standard-exhaust one-direction

propeller and are run backwards for the supply mode, producing about 40

percent of exhaust-mode airflow. Canadian Blower Fan blowers produce

100 percent airflow in either direction. Aerovent also produced an

integrated electrical control system guaranteed to work with its fans

instead of the power plant having to acquire a separate system from

another source. The system features an onboard starterdisconnect

switch, which boosts the motor s start and can be easily disconnected.

Fire safety is a challenge in any environment, and especially so in a

power plant. In case of a fire, the first priority is to ensure the

safety of employees. Another goal is to be able to salvage expensive

equipment in the building. With ventilation fans, if the motor fails

during a fire, it is more beneficial if the fan s dampers automatically

fail in the open position, and allow smoke to escape.

Canadian Blower s expertise in custom-building fans for complex

applications, like this energy center, allowed them to design and

construct a special fire damper for the fans. When the motorized damper

is activated, a metal linkage arm attached to the damper blades moves

to open or close the damper.

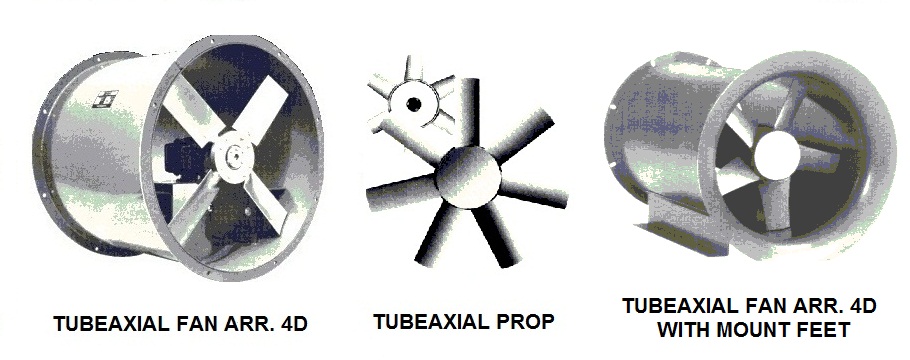

Tubeaxial Fans (industrial

tubeaxial blower fans)

Axial flow fans or industrial

axial fans use a propeller to draw the air into the fan then discharge

it in the same axial direction which makes them beneficial for small

space constraints. The way these fans work is like the propeller on an

airplane: the fan blades generate an aerodynamic lift that pressurizes

the air. Axial fans are typically selected where large volumes of clean

air need to be moved against low static pressures. There are optional

designs where vanes are added to the standard housing configuration to

allow the propeller to generate greater static pressure. They can be

used in varying environments as their construction is of painted carbon

steel, stainless steel, aluminum or FRP (fiber-reinforced polymer).

Tubeaxial fan:

axial flow through fan designed for low pressure building ventilation

and industrial process application. Uses include heat, smoke, and fume

removal; process ventilation and process air handling; proces drying

with ambient or preheated up to 650 F air; comfort process cooling and

general ventilation of buildngs. Available in direct drive arrangements

4/4M/4V/4D/4R and corresponding belt drive arrangements 9/9M/9V/9D/9R.

Capacities: to 350,000 CFM. Static pressure to 4 inches water gauge.

Aluminum fan wheel, Steel

wheel, or

Alloy wheel:

tubeaxial fan for non-sparking x-proof applications is supplied in AMCA

A, AMCA B, or AMCA C spark resistant construction in all aluminum

welded construction, or in monel. For corrosive environment tubeaxial

fan is supplied in 304 SS, 316 SS, or 316 L stainless steel

construction. For chemical process applications tubeaxial fan is

available in fiber reinforced plastic frp construction, or in

polypropylene construction, or in plastic. For high temperature

applications up to 650 F tubeaxial fan is supplied typically in steel

welded construction.

Inlet flanges, outlet flanges,

companion flanges: continuosly welded to match ANSI class 125/150,

DIN, ISO, or custom hole pattern.

Fan shaft seals:

tubeaxial fan shafting is straightened to close tolerance to minimize

"run-out" and ensure smooth operation. Bearings are of pillow plock, or

flaged bearings. Ceramic shaft seal and lubricated shaft seals (Buna,

Teflon, Viton) are standard. Red silicone gasketing is used on high

temperature applications.

Heat fan construction up to 650

F:

includes high temperature paint, shaft cooler, shaft and bearing tunel

cooling auxiliary blower (optional), insulated shaft and bearing tunel,

steel, or alloy wheel.

Cladding for sound attenuation

and silencers:

cladding consists of 2 inches mineral-wool insulation covered with a

welded steel jacket. Acoustic cloth jackets are available as

inexpensive alternative. Inlet silencers/outlet silencers are supplied

with matching flanges.

Inlet vane damper assembly:

external inlet vane damper is provided for precise air volume control.

Standard fan accessories:

flash

/ raised access door, inspection port, drain and plug, 3-way drain,

mount feet, belt guard, motor cover, spring vibration isolation,

rubber-in-share (RIS) vibration isolation, vibrating pads, electrical

actuators, pneumatic actuators.

Roof mount fan accessories:

roof curb mount cap, roof curb, weather band, weather shroud with

integral flap damper, butterfly damper assembly, magnetic latches.

Controls and drives:

variable frequency drives (VFD), across-the-line starters, RTDs,

pressure sensors, flowmeters - complete control packages.

Canada

Blower

http://cbblower.com/aircurtain.html

http://cbblower.com/airhandler.html

http://cbblower.com/blowoffsystems/Index.html

http://cbblower.com/contact.html

http://cbblower.com/coolair.html

http://cbblower.com/custserv.html

http://cbblower.com/enclosure.html

http://cbblower.com/exchanger.html

http://cbblower.com/fanblower.html

http://cbblower.com/fanblowerinquiry.html

http://cbblower.com/fumeextracting/Index.html

http://cbblower.com/heatexchange.html

http://cbblower.com/home.html

http://cbblower.com/hvac.html

http://cbblower.com/ilg.html

http://cbblower.com/illinois.html

http://cbblower.com/ige.html

http://cbblower.com/index.html

http://cbblower.com/industrialairknife/Index.html

http://cbblower.com/industrialairknives/Index.html

http://cbblower.com/industrialairmoving/Index.html

http://cbblower.com/industrialairsystem/Index.html

http://cbblower.com/industrialblowoff/Index.html

http://cbblower.com/industrialscrubber/Index.html

http://cbblower.com/industrialscrubbers/Index.html

http://cbblower.com/inquiry.html

http://cbblower.com/liquidexchanger.html

http://cbblower.com/marlo.html

http://cbblower.com/navigator.html

http://cbblower.com/neptronic.html

http://cbblower.com/news.html

http://cbblower.com/nyb.html

http://cbblower.com/silencer.html

http://cbblower.com/airblower/Index.html

http://cbblower.com/aircannon/Index.html

http://cbblower.com/aircannons/Index.html

http://cbblower.com/blowoffsystems/Index.html

http://cbblower.com/fumeextracting/Index.html

http://cbblower.com/industrialairknife/Index.html

http://cbblower.com/industrialairknives/Index.html

http://cbblower.com/industrialairmoving/Index.html

http://cbblower.com/industrialairsystem/Index.html

http://cbblower.com/industrialblowoff/Index.html

http://cbblower.com/industrialscrubber/Index.html

http://cbblower.com/industrialscrubbers/Index.html

http://cbblower.com/wetscrubbers/Index.html

Industrial blowers, OEM fans,

high temperature ventilators, high pressure blowers and high

temperature ventilator fans, industrial OEM fans, roof and wall fan

exhausters, industrial ventilating and air-conditioning fan / blower

wheels, HVAC, heating ventilation and air conditioning, process and OEM

fans / blowers, custom built fans, ventilators, dust collectors,

Buffalo - New York combustion pressure blowers, oven circulation fans.