About Us

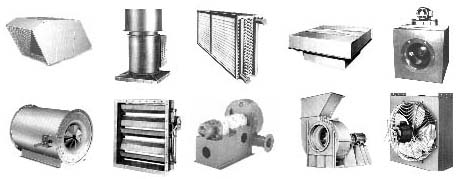

ILG COOLAIR is a leading supplier of industrial and commercial fans, ventilators, blowers and accessories for various air-moving applications.

ILG COOLAIR offers a complete line of fan equipment, from small panel fans capable of moving a few hundred cubic feet per minute, to large, heavy-duty industrial mechanical draft fans with capacities to 1,000,000 CFM and with static pressures from 0" Water Gauge (WG) to 150" WG.

ILG COOLAIR products include standard

centrifugal fan and axial fan designs as well as custom

manufactured fan units to meet our customers' requirements based on

ILG

COOLAIR manufacturing standard.

Canada Blower centrifugal blowers

have many applications including general ventilation, those requiring

high airflows, manufacturing process, emergency or continuous high

temperature, or grease-laden exhaust. Material choices range from

galvanized steel, steel with corrosion resistant coatings, aluminum,

fiberglass, or stainless steel. Designs are tiered to provide the most

economical, practical and efficient operation by performance

requirements and application.

Over the years ILG COOLAIR supplied fans to a wide range of industries and applications including: combustion air supply, material handling, process ventilation, ovens and dryers, iron and steel industry, mine and tunnel ventilation, petro-chemical, power generation, marine and off-shore structures, pulp and paper, HVAC, paint/spray booths, fertilizer and various emission control applications. For the commercial HVAC market, ILG COOLAIR offers general ventilation fans for institutional and retail buildings, schools, restaurants and hospitals. Special materials, construction, explosion-proof and spark-resistant design, variety of coatings and accessories are available to meet practically any application needs.

ILG COOLAIR air moving products are best know for "industrial quality" assuring reliable performance, relentless dependability and longevity. A staff of specially trained engineers will design a dependable fan that exactly fits customers' dimensional and performance requirements.

ILG COOLAIR fans and blowers are sold and serviced by air moving experts that can evaluate your needs and provide best recommendations for your application.

Suppliers of cool air blowers, high volume air ventilators, air blower motors, Canada Blower pneumatic blowers, compressed air blowers, suction pressure blowers, air blower compressores, high pressure axial fans, propeller fans, axial prop fans, industrial fan motors, big industrial fans, large industrial ventilators, industrial blower systems, explosion proof ventilation fans, rooftop fans and ventilators, shop fans, building ventilation fans., , high temperature oven fans and blowers, centrifugal and axial blowers and fans. Buffalo Blower industrial high temperature pressure blowers, high pressure fans, high volume industrial pressure blowers. Sales of Canadian Blower pressure blowers and Buffalo Blower OEM industrial fans, roof and wall exhausters, ventilating and air-conditioning equipment, pressure blower HVAC, heating ventilation and air conditioning, process and OEM blowers, Chicago Blower custom built fans, ventilators, high temperature oven exhaust, combustion pressure blowers.s.

Backwardly inclined (BI) fan blowers and aerofoil (AF), acoustafoil (AcF), or aerocline fan blowers from New York; with high temperature construction, low leakage, 87 % efficiency, stainless steel SS316, SS316L, SS304, aluminum construction, spark resistant construction, monel construction. Supply of replacement bacward inclined (BI) fan blowers and airfoil (AF), or acoustafoil (AcF), or Aerocline fan blower parts for backward inclined bi fan blowers manufactured by Buffalo Blower / New York Blower, Twin City Fan, Northern Blower, Chicago Blower, Sheldons, Cincinnati Fan, Hartzell, IAP, Industrial air products, Canadian blower, Howden Buffalo, Penn Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent, Alphair, American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan, Daltec, ABB, Flakt, Flaktwoods, Woods, MK Plastics, Robinson Industrial, Garden City Fan, Loren Cook, Jen-air, Jenn Fan, Aeroflo, Grainger, Greenheck, Kice Fan, ILG Industries, Canada Fan, Industrial Air, Ceilcote, Breidert; high pressure and high temperature pressure blowers.

Canada Blower Co. has developed high pressure blowers-in-series systems to achieve static pressure, previously unachievable by single stage centrifugal blowers.

Series and parallel connected blower installations are often used to meet performance ranges beyond normal single stage blower capacities. For systems that require high ststic pressure, and especially high pressure TOGETHER with high temperature (where standard multi stage, positive displacement, screw, or regenerative type blowers can not be used) series of single stage centrifugal blowers can be used. Many times additional blower in the system can be advantageous. For instance, where two blowers are operating in series and one breaks down, the other may be able to "limp" the system along while the necessary maintenance is performed. Having on blower continue in operation can often allow limited production while the other is being repaired. Also, there are cases where having one blower continue in operation could prevent or at least minimize system or equipment damage from such things as high temperature ot contaminated airstreams.

Another advantage of blowers in series is that of the availbale space. If system must be expanded and increaases the CFM requirements, the allotted space for the original blower may not be large enough for a single large blower, but might be large enough to istall two smaller blowers in series to obtain the necessary pressure.

One more potentail advatage for series operation is the likehood of initial cost savings. Although each case must be evaluated individually, it is often more economical to select two "smaller" blowers with their respectice smaller motors and drives than to select one "larger" blower to do the job.

Series connected blowers are those which have the outlet of the one blower exhausting into the inlet of another blower. By connecting blowersa in such a manner, high static pressures can be attained. This is accomplished as the second blower adds its pressure capability to the system, increasing the capacity beyond the capabilities of the first blower.

Ideally, two identical blowers installed in series would result in the same CFM at the outlet of the second blower as the inlet of the first one, and nearly twice the static pressure as that rated for either blower alone. However, some variation will result in both air flow and combined pressure because of the tendency of air to compress under pressure. A good understanding of how atnoshperic pressure and absolute temperature affect density is required. Both of these factors are involved in the proper selection of blowers. Density is directly proportional to atmospheric pressure and is inversely proportional to absolute temperature (degrees Rankine).

Caution is necessary in selecting blowers for series installtion. It is generally accepted that most pre-engineered blowers are capable of withstanding twice their catalog rated static pressure. In other words, where two blowers are installed in series the second blower housing should withstand the higher pressure. There is, however, a need for concern when the combined pressure exceeds twice the rated static pressure for one blower. In series applications involving three or more blowers, or in any system in which positive or negative pressure exists prior to the consideration of the blowers, special housing reinforcement may be necessary.