Air Curtains manufactured by experts !

Air curtains provide a controlled stream of air across a building entrance or doorway to separate interior atmosphere from exterior environment. Air curtain’s airstream prevents cold, hot, or humid outdoor air, as well as insects and dust, from infiltrating the inside the building. This is why Air Curtains are considered as the first line of defense for employee safety.

Although air

curtains require power to run the blowers and fan heaters, Air Curtains

save much more costs by reducing drive-thru time, window wind fume

hazard, providing low-first cost and low total cost as well as

additional energy savings in energy battle.

Canada Blower air curtains provide a controlled stream of air

across a building entrance or doorway to separate interior atmosphere

from exterior environment. Air curtain’s airstream prevents cold, hot,

or humid outdoor air, as well as insects and dust, from infiltrating

the inside the building. This is why Air Curtains are considered as the

first line of defense for employee safety.

Although air curtains require power to run the blowers and heaters, Air

Curtains save much more costs by reducing drive-thru time, window wind

fume hazard, providing low-first cost and low total cost as well as

additional energy savings in energy battle.

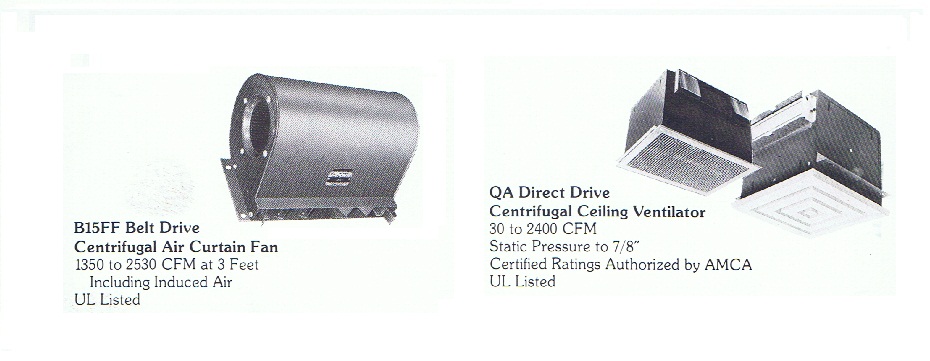

Canada Blower Air Curtain Comstruction typically an air curtain will

incorporate double width blower, belt, or direct driven, heating /

cooling coils, or a gas fired coil, electrical controls, such as door

plunger switch, speed controller, disconnect switch, and others, and

mounting accessories, such as mounting brakets for suspended, or

verhead mount.

Design Consdierations: To properly design an air curtain application

the airstream must hit the floor with enough velocity to create a

stable split right at the doorway. Design criteria for selection of

proper air curtain for a given application include height and width of

the door opening, intended usage, required characteristics of the

airflow, which are combination of velocity, volume, and uniformity and

the proper balance between each.

Once an air curtain is activated, it creates a split which uses the

internal pressure to resist infiltration of temperature, rain, wind,

debris, insects, etc. among the conditioned indoors and unconditioned

outdoors air.

Typical applications for Canada Blower air-curtains include Commercial

various entrances, loading doors, hotels, hospitals, stores, public

facilities, and other commercial buildings, and other applications,

such as Food service, where all aluminum, or all stainless steel air

curtains are utilized .

While Canada Blower air curtains have been commonly used for decades to

separate environments in the workplace, perhaps now is the time safety

professionals should consider them to help eliminate

industrial/commercial doorway accidents as well as keep restaurant

drive-thru employees safe from CO poisoning and wintertime temperature

extremes.

Typical applications include various entrances, loading doors, hotels,

hospitals, stores, public facilities, and other commercial buildings,

and other applications.

ILG Canada Blower air curtains are supplied with optional easy mounting

trim key.

Air Curtain Construction typically an air curtain will incorporate double width blower, belt, or direct driven, heating / cooling coils, or a gas fired coil, electrical controls, such as door plunger switch, speed controller, disconnect switch, and others, and mounting accessories, such as mounting brakets for suspended, or verhead mount.

Design Consdierations: To properly design an air curtain application the airstream must hit the floor with enough velocity to create a stable split right at the doorway. Design criteria for selection of proper air curtain for a given application include height and width of the door opening, intended usage, required characteristics of the airflow, which are combination of velocity, volume, and uniformity and the proper balance between each.

Once an air curtain is activated, it creates a split which uses the internal pressure to resist infiltration of temperature, rain, wind, debris, insects, etc. among the conditioned indoors and unconditioned outdoors air.

Typical applications include Commercial various entrances, loading doors, hotels, hospitals, stores, public facilities, and other commercial buildings, and other applications, such as Food service, where all aluminum, or all stainless steel air curtains are utilized .

While air curtains have been commonly used for decades to separate environments in the workplace, perhaps now is the time safety professionals should consider them to help eliminate industrial/commercial doorway accidents as well as keep restaurant drive-thru employees safe from CO poisoning and wintertime temperature extremes.

Typical applications include various entrances, loading doors, hotels, hospitals, stores, public facilities, and other commercial buildings, and other applications.ILG air curtains are supplied with optional easy mounting trim key.

All models wall fans bear the AMCA Certified Ratings Seal.

http://olegsystems.com

http://olegsystems.com/airfoil-fans/

http://olegsystems.com/axial-fans/

http://olegsystems.com/ventilating-fans/

http://olegsystems.com/heavy-duty-fans/

http://olegsystems.com/industrial-exhaust/

http://olegsystems.com/airprop-fans/

http://olegsystems.com/frp-construction/

http://olegsystems.com/price-list/

http://olegsystems.com/contact-us/

http://olegsystems.com/in-line-belt-driven-fan-price-chart/

http://olegsystems.canadablower.com/industrial-axial-inline-direct-driven-fans-price-chart/

http://olegsystems.canadablower.com/industrial-centrifugal-fans-price-chart/

http://olegsystems.canadablower.com/industrial-centrifugal-blowers-price-chart/

http://olegsystems.canadablower.com/wall-exhauster-price-chart/

http://olegsystems.canadablower.com/roof-exhauster-price-chart/

http://olegsystems.com/wall-and-roof-supply-fans-price-chart/

Sales engineers for

high temperature oven circulating fans, sandblast blowers, stainless

steel fans blowers, vacuum blowers, corrosion resistand fans, chemical

resistant blowers, air table blowers, Aerovent Fan ventilators, fume

fans, high temperature fans & blowers, Industrial Air Products

fans, LAU ventilators, CBC fans, Peerless Blower fans, high vacuum

fans, wall fan ventilators, power roof ventilator fans.

Canada Blower's Pressure Blowers in Stock:

The American Society of Heating, Refrigeration, and Air Conditioning

Engineers (ASHRAE) has established a general guideline of 20 cubic feet

of outside air per minute/per person for an office environment. This is

a sufficient amount of air to dilute building contaminants and maintain

a healthy environment. Indoor air quality complaints increase

significantly in offices that are not supplied sufficient outside air.

Indoor Air Quality (IAQ) is an increasingly important issue in the work

environment. The study of indoor air quality and pollutant levels

within office environments is a complex problem. The complexity of

studying and measuring the quality of office environments arises from

various factors including:

- Building floor plans are frequently changing to accommodate

increasingly more employees and reorganization.

- Office buildings frequently undergo building renovations such as

installation of new carpet, modular office partitions and free-standing

offices, and painting.

Many of the apparent health symptoms are vague and common to both the

office and home environment. Guidelines or standards for permissible

personal exposure limits to pollutants within office buildings are very

limited.

Many times odors are associated with chemical contaminants from inside

or outside the office space, or from the building fabric. This is

particularly noticeable following building renovation or installation

of new carpeting. Out-gassing from such things as paints, adhesives,

sealants, office furniture, carpeting, and vinyl wall coverings is the

source of a variety of irritant compounds. In most cases, these

chemical contaminants can be measured at levels above ambient (normal

background) but far below any existing occupational evaluation

criteria.

Various building studies indicate that the most likely sources of this

problem are - poor ventilation, poor thermal conditions, too high or

low humidity, emissions from office machines, copiers and other

building contaminants and poor ergonomic layout of workstations.

Air enters office buildings or spaces through both mechanical

ventilation systems as well as naturally through leaks around windows,

doors, etc. Newer, larger buildings which are highly energy efficient

due to sealed windows and heavy insulation primarily depend on

mechanical ventilation. Older, small, and low occupancy office

buildings can be adequately ventilated through natural sources which

include air leakage through opened windows and doors, as well as

through cracks in the windows and walls, and other openings.

In a modern office building, the heating ventilation and air

conditioning system is designed to keep occupants comfortable and

healthy by controlling the amount of outside air that is added to the

building atmosphere, filtering both incoming and recirculated air to

remove particulates and controlling the temperature. The HVAC system

includes all heating, cooling, and ventilation equipment serving a

building: furnaces or boilers, chillers, cooling towers, air handling

units, exhaust fans, ductwork, filters, steam (or heating water)

piping. A ventilation system consists of a blower to move the air,

ductwork to deliver air to the room, and vents to distribute the air. A

good ventilation design will distribute supply air uniformly to each

area and especially areas with office machines. An effectively designed

area will not have the supply and exhaust vent too close together

because fresh air may be removed before it is adequately distributed

throughout the area. Exhaust fans are often located a significant

distance away from supply vents. A simple way to determine if the

ventilation system is running a vent as a supply or an exhaust is by

holding a tissue near the vent.] If the tissue moves, the air is being

circulated and the direction the tissue is blown will determine the

type of vent.

A ventilation system should provide for a comfortable environment with

respect to humidity and temperature. The overall goal of climate

control is to provide an environment that is not too cold, hot, dry or

humid, and that is free from drafts and odors. Humidity refers to the

amount of moisture in the air and extremes in humidification levels can

influence how comfortable you may be. When the air is too humid, it

makes people feel uncomfortable (wet, clammy) and can promote mold

growth. On the other hand, low humidity conditions (which typically

occur in the winter months) dry out the nasal and respiratory passages.

Low humidity may be associated with an increased susceptibility to

upper respiratory infections. Static electricity problems (affecting

hair and clothes, particularly synthetic fibers) are good indicators of

an office with low relative humidity.

OTHER CANADA BLOWER EQUIPMENT AVAILABLE:

- industrial and commercial fans and blowers;

- air handling units;

- heat exchangers;

- fume extractor fans;

- dust collectors, air scrubbers.